Model 1325 CNC router machine, the middle horizontal axis, is mainly used for cutting and engraving small complex patterns on the workpiece and drilling holes on multiple sides of the workpiece, especially suitable for grooving the sides of wooden doors.

The sunken table increases the height of the products processed by customers. In addition, the swivel attachment on the side of the table is used to sculpt furniture legs and 3D statues. It is a multi-axis milling machine for economical costs such as furniture decoration or 3D artwork or advertising industry.

What is The Best CNC Router for My Business?

Configurations of Multi-Head CNC Wood Router Machine

1 Work Area: 1300mm*2500mm*200mm

2 Packing Size: 3200*2200*2000

3 3.5kw air-cooled Spindle

4 YAKO Setpper Motors and Controllers

5 vacuum pump 5.5kw

6 T-slot and vacuum table, pump

7 Taiwan 20mm PMI Linear Guide

8 Mach3 controller system

9 Drive system: X and Y-axis:

10 3.7kw inverted

11 Two Bag Dust Collection System

12 plywood case package

13 Oil mist cooling system

14 Rotary: 200*2500mm

15 380V 3PH 50HZ working voltage

Machine Video

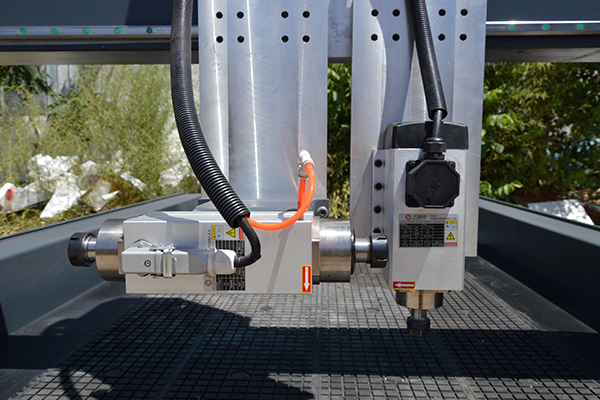

Machine Pictures of CNC Router with Horizontal+Vertical Spindle

Vacuum Table

Lubrication System

Stepper Motor

Horizontal+Vertical Spindle

Rotary Axis

Control Button

Applications of Wood CNC Router

Wood furniture industry: wave boards, fine patterns, antique furniture, wooden doors, screens, craft window sashes, composite doors, cabinet doors, interior doors, sofa legs, headboards, etc.

Advertising industry: Advertising logo, sign production, acrylic engraving and cutting, crystal word production, blast molding, and other advertising material derivatives production.

Mold industry: engraving of metal molds such as copper, aluminum, iron, etc., as well as non-metal molds such as artificial marble, sand, plastic cloth, PVC pipe, and wood.

Embossed and 3D sculpted and cylindrical objects.

Suitable Materials of Multi-Head CNC Wood Router Machine

- Wood: Solid wood, MDF, Plywood, Chipboard.

- Plastic: PVC, ABS, Acrylic, Plastic.

- Marble: Artificial Stone, Marble, Granite, Ceramic,

- Sign Material: Foam, Cupboard, Styrofoam, Leather, Plastic carpet, corrugated paper,

- Metal: Steel, Metal, Stainless, Pipe, tube, Corrugated metals, expanded metal, or flat sheet stock.

- Soft Metal: Aluminum, Brass,

- Composite: Aluminum Composite, Copper Composite, Titanium Composite, Zinc Composite.

igor Sergienko –

6 spindle with 6 rotary CNC Wood Router Machine.We only purchased the engraving machine to make our table legs We practised many times and I luckily to say thanks FORSUN for awesome service.The machine is really nice and clean.And it’s very efficient.And the service ia really very great.Thanks

zyx –

Thank you for your feedback and look forward to working with you next time.

igor Sergienko –

Hi, Need to process cutting WPC foam board

Need fast efficient machine to decrease manufacturing time

FORSUN –

Hello Sir,This is Dora,thanks for your inquiry, our cnc router can do WPC foam materials mwhat working size machine do you need?

Chí Huy –

very nice product, works perfectly, and very well pack, good feeling with the seller and he was very responsive.

GIOVANNI LETRAN –

This new machine is so awesome. Easy to set up, and run, works very well. I had some minor issues getting started so I contacted FORSUN for assistance. Although there is a time difference they were quite helpful in getting me sorted out. Good customer service, they really to care. I would definitely buy again!

Pawel –

Great product and great customer service! We weren’t sure how to use some of the features of the rotary program and Forsun company was very helpful in making sure everything was working for us. They even remote accessed our computer to show us how to use the rotary features. The product itself is great and will engrave almost any material from polymer to hard steel.

Javier Frappe –

Hi ,how much does it a 5 axes metal and wood cnc with 380 x 250 working bed. with pc connecting ready

FORSUN –

Thanks for your inquiry . This is Jessica from FORSUN , can you tell me what material you need to process?

Majdi Wafaei –

Hi, I need to drill holes in wood, different diameters, and angle positioning.

How fast can you send here one machine? Can you show me a little test with a sample of wood according to a technical drawing I can send you?

FORSUN –

Hi, yes, we can make the test according to your drawing. Could you send us?

ZhuGuanRou Gui –

I need a 1800×1800 machine.

And will use 1.0 endmill

Is it possible for the AL plate? (1.0 thickness)

Is a CNC router possible?

FORSUN –

Hello dear, this is Dora, Thanks for your inquiry,

Our cnc router can do AL, and it suits 1.0endmill

1800*1800mm size is no problem, please let me know if you only to cut AL 1mm thickness?