CNC Foam Cutter Router

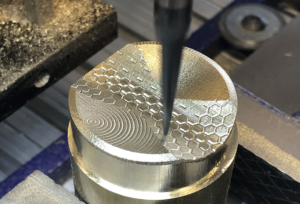

CNC EPS cutting machine is the heavy-duty CNC Router for all kinds of mold making. Such as wooden wood, Foam mold, aluminum mold, and other non-metal molds. This foam CNC router machine is designed with a special machine structure and installed with a high configuration in order to get high speed, high precision, and good performance. The important machining parts of the EPS cutting machine tool are subjected to annealing and other heat treatment processes. After the machining is completed, the three-coordinate measurement is performed to ensure the accuracy of the parts.

This CNC foam cutter is widely used in the production of various molds. Lost molds, automobile foam molds, plaster molds, paraffin molds, large ship wood molds, aviation wood molds, propellers, train wood molds, etc.

Due to the many disadvantages of the traditional hand-made molds, including the uneven foam balance used in castings and the omission of mold parts and components. This not only greatly affects the efficiency of mold processing, and thus affects the overall quality and production cycle of the mold. In order to improve the production status of this mold processing. With the advantages of uniform margin, fast processing speed and high processing quality, this cnc foam cutter machine is widely used in the mold industry, which not only improves the quality of mold castings, but also shortens the mold production cycle. Therefore, these foam CNC router is welcomed by users in the mold industry.

Other hot CNC machine collections: wood cnc machine, 4 axis cnc router, 5 axis CNC router, cnc plasma cutter, stone CNC router, ATC CNC router, mini CNC router