Description of Portable CNC Plasma Cutter for Precision Metal Cutting

The Portable CNC Plasma Cutter for Precision Metal Cutting is designed for flexibility and high-performance metal cutting in various industries. Ideal for on-site use or small workshops, this CNC-powered plasma cutter delivers clean, precise cuts on metal sheets with exceptional speed and accuracy. Its portable design allows for easy transportation and setup, making it perfect for fabricators, contractors, and metalworkers who require mobility without compromising on quality.

Equipped with advanced CNC technology, this plasma cutting machine offers automatic height control, ensuring consistent cutting quality across different material thicknesses. It supports a range of metals, including steel, aluminum, and stainless steel, making it a versatile choice for a wide range of applications.

With its intuitive control system, the portable CNC plasma cutter provides users with an easy interface for quick setup and operation, even in demanding environments. Whether you’re working with large sheets or intricate designs, this machine is built to handle various cutting tasks with precision and efficiency.

What is The Best CNC Plasma Cutter for My Business?

Work video:

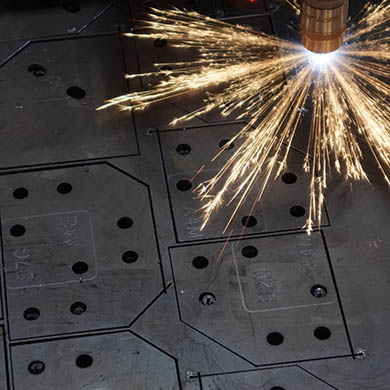

Plasma Cutter Pictures Gallery

63A LGK Power Source

63A LGK power source can perforate and cut 0.5MM-30MM, and the edge can cut 40MM metal materials. It adopts air-cooling, water-cooling, and other cooling methods. It is equipped with an imported metal cutting torch as standard, which completely solves the problem of a burning torch. It comes with arc voltage adjustment, slit compensation, and an anti-collision system. It can work continuously for 24 hours.

Fang Ling Control System

Automatic arc voltage height control: During the cutting process, the height of the steel plate will be automatically tracked, and the cutting torch and steel plate will always be kept at a fixed height to ensure the cutting quality.

Intelligent adjustment of arc voltage: After multiple collisions, the set arc voltage will automatically increase.

Collision feedback: feedback the collision signal to the control system immediately after the collision.

Plasma Torch Height Controller

During the cutting process, the height of the steel plate will be automatically tracked, and the cutting torch and steel plate will always be kept at a fixed height to ensure the cutting quality.

Plasma Cutting Head

Linear Guide

The aluminum alloy track is equipped with a steel linear slide rail, which fully guarantees the equipment operation accuracy, is easy to install, and is durable.

Cable

The drag chain follow-up mechanism is adopted to ensure the cleanliness of the pipeline. And can reduce the overshoot tendency of the machine when turning at high speed. It can prevent the pipeline from being worn out due to the high-speed cutting and walking during the cutting and judging motion, and at the same time, it can save unnecessary pipeline length.

Applicable industry & materials

Shipbuilding, construction equipment, transportation equipment, aerospace, bridge construction, military industry, wind power generation, structural steel, boiler containers, agricultural machinery, chassis electrical cabinets, elevator manufacturers, textile machinery, environmental protection equipment, etc.

Aluminum, copper, titanium, nickel, iron, galvanized sheet, white steel, titanium sheet, carbon steel, stainless steel, alloy steel, composite metal, etc.

Benefits

The Portable CNC Plasma Cutter for Precision Metal Cutting features a new portable design with a manual handling structure, making it incredibly flexible and easy to move around. Despite its compact size, this machine can handle cutting metal plates up to 4ft x 8ft, thanks to its X and Y-axis travel of 1300 x 2500mm. This portability allows the plasma cutter to be positioned exactly where it’s needed for efficient production.

For example, when dealing with large metal plates, such as an 8-meter long steel plate that is difficult to move, the portable CNC plasma cutter offers an ideal solution. Simply bring the plasma cutter to the steel plate, place it in position, and start the cutting process. This mobility is the key to cutting large metal materials with ease and precision.

Key Features:

-

Fast Cutting Speed & High Precision: Achieve cutting speeds of over 20m/min with high precision, resulting in thin, clean cuts that reduce the need for secondary processing.

-

Wide Cutting Area: Capable of cutting a variety of metal sheets, making it suitable for a broad range of applications.

-

No Deformation: Underwater cutting prevents material deformation, and fine plasma cutting offers superior precision.

-

Small Inner Contours & Holes: Perfect for intricate designs and smaller cutting tasks.

-

User-Friendly Operation: Equipped with a professional CNC system for offline work and intuitive operation. The user-friendly controller ensures ease of use.

-

Software Compatibility: Compatible with a range of software, including CAD/CAM-controlled production, to streamline the cutting process.

-

Cost-Effective: Lower investment and operational costs compared to fiber laser cutting machines, making it a highly affordable option for businesses.

-

Durable & Reliable: Factory-direct pricing with a one-year warranty ensures long-term value and peace of mind.

This portable CNC plasma cutter is ideal for fabricators, metalworkers, and contractors who need a reliable, efficient, and affordable metal cutting solution on the go.

Technical Data of the Portable Plasma Cutter

Model Name

Plasma Cutting Machine FS1325P

X, Y Axis Travel

1300X2500mm(4X8ft), Option: 600*900mm, 2000X3000mm, 2000X4000mm, 1500X3000mm(5X10ft)

Z Axis Travel

200mm, Option; 300mm,400mm, 500mm,600mm.

Rotary Axis

200mm(diameter)*2500mm

Plasma Power

63A,Option:100A,105A,120A,160A,200A

Power Source Brand

LGK, Option: Hypertherm, Thermadyne, Victor,

Drive System X, Y and Z axis

German Helical Rack and Pinion for X and Y-axis. And Z-axis with TBI ball screw

Transmission X, Y, and Z-axis

HIWIN/THK Rail Linear guide and bearings.

Motor for X, Y, and Z

Stepper motor / AC Servo motor

Machine Structure

Thicken weld steel tube machine body. Rigid gantry and side support, Professional Plasma cutter table

Working Voltage

220V/50HZ/60HZ,3PH or 380V/50HZ/60HZ,3PH

Command Language

G Code & M Code

Operating System

Fang Ling Control System

Lubrication

Automatic lubrication system

Max. Rapid Travel Speed

40000mm/min

Max. working Speed

25000/min

Machining Function

carbon steel 0-50mm cutting thickness and stainless steel 0-20mm cutting thickness

Compatible Software

FastCam, Ucannest

Other Names

CNC plasma cutter, CNC plasma cutting machine, plasma CNC machine, CNC plasma cutter price, cheap CNC plasma cutter, small CNC plasma cutter, CNC plasma for sale, CNC plasma router, best CNC plasma cutter, CNC plasma machine for sale, mini CNC plasma cutter, CNC plasma cutting machine manufacturer

Suitable Materials

Stainless steel, mild steel, brass, copper, aluminum alloy, sheet metal, spring steel, gold, silver, etc

Applications

Sheet metal, kitchenware, components, decorations industry

Gross Weight

2200 KGS

Package Size

3700*2250*1850mm

Why choose FORSUN CNC?

Thicken weld tube machine frame for high performance and material processing.

Heavy-duty frame milling and drilling by machining center to keep high accuracy.

Sandy blasting putty and rusty cleaning before painting to prolong machine body use.

Material incoming inspection to make sure machine quality in the very beginning.

During the CNC Router installation process, precision instruments are used to ensure the accuracy of the CNC Router Machine installation.

After the CNC Router is installed, use the testing instrument to test the Vertical accuracy, traveling accuracy, working accuracy, repeated positioning accuracy, etc.

Working Procedure of CNC Plasma Cutter

-

Convert the Working File: Begin by converting the working file to DXF format using AutoCAD or by utilizing existing SolidWorks files.

-

Import Drawing for Nesting: Import the parts drawing in DXF or DWG format into the FastCAM software for nesting and conversion. This software will process the design and generate the NC program (typically in G-code or EESI format).

-

Transfer NC Program to Plasma Cutter: Copy the converted NC program (G-code file) to the plasma cutting machine controller system using a USB disk.

-

Set Working Parameters: Set the necessary working parameters according to the material type and thickness specified in the program.

-

Adjust Torch Position: Adjust the position of the plasma torch on the metal plate, ensuring it’s properly aligned.

-

Start Cutting: Begin the cutting process by initiating the program. The plasma cutter will execute the commands for precise metal cutting.

-

End Cutting & Slag Removal: After the cutting process is complete, perform slag removal to ensure clean, high-quality cuts.

This easy-to-follow process ensures that the Portable CNC Plasma Cutter for Precision Metal Cutting delivers accurate, efficient, and reliable results, all while maintaining high production flexibility.

FAQ

- I don’t know anything about this machine, which one should I choose?

Very easy to choose. Just tell us what you want to do with the plasma cutting machine, and then let us provide you with perfect solutions and suggestions. - When I bought this machine, I didn’t know how to use it. what should I do?

We will send the video and English manual along with the equipment. If you still have questions, we can talk via phone or WhatsApp, and email. - What should I do if there are some problems with the machine during the warranty period?

If there is a problem with the machine, we will provide parts for free during the machine warranty period. Therefore, if you have any questions, please let us know and we will provide you with a solution. - Before sending me an inquiry about our plasma cutting machine, it is best to provide me with the following information

- Your cutting size. Because in our factory, we have different models according to the working area.

- Your material: carbon steel, stainless steel, aluminum, or other materials

- What is your cutting thickness?

- We will recommend the right machine for you according to your cutting thickness

Reviews

There are no reviews yet.