Introduction

Stone cutting has significantly evolved with CNC technology, allowing for more precision, efficiency, and flexibility in fabrication. Whether you’re crafting intricate sculptures, architectural elements, or engraved plaques, a CNC router with a rotary axis can take your stone processing capabilities to the next level. This advanced technology enables complex 3D carving, cylindrical engraving, and precise detailing that would be extremely difficult with manual methods.

In this article, we will explore the benefits, applications, and best practices for using a CNC router with a rotary axis for stone cutting.

At Jinan FORSUN CNC Machinery Co., Ltd. (Shandong FORSUN CNC Machinery Co., Ltd.), we have been manufacturing and supplying high-quality CNC routers for over 20 years. Our expertise covers a range of computerized CNC machines, including wood CNC routers, 3D CNC carving machines, ATC CNC routers, mini CNC routers, and CNC nesting machines. With extensive industry experience, we provide reliable guidance for businesses looking to optimize their CNC machining processes.

Understanding CNC Routers with Rotary Axis

What is a CNC Router with a Rotary Axis?

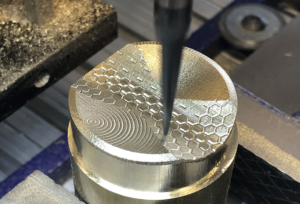

A CNC router with a rotary axis is a computer-controlled cutting machine designed for 3D engraving, carving, and shaping of cylindrical or irregular stone workpieces. Unlike standard CNC routers that work on flat surfaces, a rotary axis allows the spindle to rotate the material, enabling precise multi-sided carving.

Key Features of a CNC Router with Rotary Axis for Stone Cutting

- Rotary Engraving Capability – Allows intricate 360-degree carvings on stone.

- High-Speed Cutting – Faster and more accurate than manual carving methods.

- Wide Material Compatibility – Suitable for marble, granite, sandstone, limestone, quartz, and other stones.

- Automated Tool Changes – Some models feature ATC (Automatic Tool Changer) for efficiency.

- Advanced CAD/CAM Compatibility – Enables customized designs and precise detailing.

Benefits of Using a CNC Router with Rotary Axis for Stone Cutting

1. Superior Precision and Detailing

- CNC routers ensure flawless, highly detailed engravings, which are impossible to achieve manually.

- The rotary axis allows for smooth curves, intricate patterns, and consistent symmetry.

2. Increased Production Efficiency

- Eliminates manual repositioning, reducing downtime.

- Continuous operation leads to higher output and faster production cycles.

3. Versatility in Stone Fabrication

- Ideal for architectural details, religious sculptures, custom stone furniture, and artistic engravings.

- Capable of handling both simple and complex projects with ease.

4. Minimized Material Waste

- CNC precision reduces errors, leading to efficient material usage and lower costs.

- Consistent quality ensures minimal rework or rejected pieces.

5. Lower Labor Costs and Increased Automation

- Reduces the need for skilled manual labor, making production more cost-effective.

- Automation enhances consistency and reduces human error.

How to Optimize Stone Cutting with a CNC Router & Rotary Axis?

1. Select the Right Cutting Tools

- Use diamond-tipped router bits for durability and precision.

- Choose tools based on stone hardness and desired finish.

2. Properly Secure the Stone Workpiece

- Ensure stable clamping to prevent movement during engraving.

- Position the material correctly for accurate cutting paths.

3. Optimize Cutting Speeds and Feed Rates

- Adjust speeds based on stone density – harder stones require slower speeds for precision.

- Set the correct feed rate to prevent tool damage and ensure smooth cutting.

4. Maintain the CNC Router and Rotary Axis Regularly

- Clean the rotary axis and tool holders after each use.

- Lubricate moving parts to prevent wear and tear.

- Check for bit sharpness and tool alignment to maintain accuracy.

5. Use High-Quality CNC Software for Design and Execution

- CAD/CAM software allows for precise design planning before cutting.

- Optimize toolpaths to reduce tool wear and enhance efficiency.

Control cabinet

Computer

Marble cutting saw

80°adiustable table

Dust cover

Wood table

Common Applications of CNC Routers with Rotary Axis in the Stone Industry

1. Architectural and Decorative Stonework

- Carving intricate columns, stair balusters, and ornate facades for high-end buildings.

- Creating detailed wall panels and artistic inlays.

2. Memorial and Tombstone Engraving

- Producing high-precision lettering, portraits, and symbols on headstones.

- Customizing memorial designs with deep and long-lasting engravings.

3. Religious and Cultural Sculptures

- Fabricating Buddhist, Hindu, or Western religious statues with precise details.

- Carving intricate temple pillars and spiritual artifacts.

4. Custom Stone Furniture and Home Décor

- Designing personalized stone tabletops, vases, and artistic décor pieces.

- Engraving custom patterns for high-end interior design projects.

Challenges in Stone CNC Routing and How to Overcome Them

1. Tool Wear and Breakage

- Solution: Use high-quality, wear-resistant diamond tools and adjust feed rates accordingly.

2. Dust and Debris Buildup

- Solution: Install a high-powered dust extraction system and clean the workspace regularly.

3. Programming Errors

- Solution: Double-check CNC programming and simulation before running the machine.

4. Machine Calibration Issues

- Solution: Regularly calibrate the CNC router to ensure precision and alignment.

Conclusion

A CNC router with a rotary axis is an essential tool for modern stone fabrication, offering unparalleled precision, speed, and versatility. Whether you specialize in stone sculptures, architectural carvings, or memorial engravings, this technology can enhance your production quality and efficiency.

At FORSUN CNC, we manufacture high-performance CNC routers built for professional stone cutting applications. Our machines are designed for precision, durability, and efficiency, helping businesses achieve superior results in stone engraving and carving.

Looking to upgrade your stone-cutting capabilities?

Contact us today to explore our advanced CNC stone routers with rotary axis and find the perfect solution for your needs!