Are you a new user for CNC Routers? Do you know how to use a CNC Router?

Right, this is a detailed beginner’s guide to operating a CNC Router Machine!

What’s a CNC Router? How to choose a CNC Router?

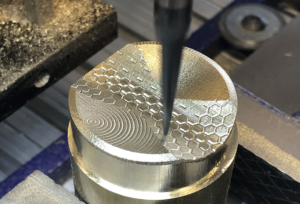

CNC router, also known as computer numerical control router machine, is a computer-controlled device used to carve out or cut through hard materials like wood, plastic, aluminum, etc.

CNC routers have varying configurations, from large industrial CNC routers to small homemade routers.

Click here to read more >>

Know each part of the CNC router

Before we teach you how to use a 3D CNC Router, we would like to decomposite the CNC router. To be an operator, we must understand each part of the CNC router but just only know the press button. Let’s start with the cabinet first.

- Buttons on the cabinet

There are usually Green buttons, red buttons, an Emergency button, Dust collector Switch, Vacuum pump switch on the cabinet. The green button is for the machine to start while the red one is for power off. When there is an accident happens, the emergency button is used to help stop the machine immediately. Dust collector switch is to power on/off the dust collectors while the vacuum pump switch is for pumps.

- CNC router controller

Many controllers can be chosen. But mainly two big models. One is with panel operation. The other one is controlled by the PC. The world-famous brand controller includes Siemens, Fanuc, Syntec, Weihong, Mach3, Osai, DSP and so on.

- Electrical parts

A CNC Router machine good or not, the electrical parts and cable laying is the core. These all hide in the cabinet. So some suppliers make very simple and not responsible. Esp when you buy this machine for the furniture working, to choose a brand CNC router manufacture is very necessary but not only cares about the cheap price. Cheap never means quality. The cable should be marked as what it is used for. This will help you to solve problems fast and easily during use. And world-famous brand electrical parts can be ensured the quality and replaced easily in the future.

- Spindle

CNC machine moves much faster than you think. It is very rare to do something once the spindle works wrong. It may hurt the material or the vacuum table. A crash could be your fault. Or could be your mistake operations on the buttons. It may not be your fault but machine problems. So keep spindle running slow to fast step by step and keep away from the machine is the best way.

How to use a CNC Router equipment?

- A professional CNC router operator

CNC router operators must have excellent mechanical aptitude and experience with equipment, such as precision grinders, machine cutters. In addition to having strong troubleshooting and problem-solving skills, they also must have good analytical skills and be able to read blueprints and mechanical drawings.

- CAM software operation

Using the CAM software is essential but cannot be avoided. To use the CAM software to make design, tool path, and export G- code will never disappear. In the old days, designers use CAD to design and input to CAM. But they are all out of fashion now. You have to set everything in CAM software for saving time. - 3 Controller operation

To use the controller is the first step.It runs the machine in fact. You have to learn each detail of the CNC Router machine. Jogging the machine, loading files, home, XYZ moving, auto cycle start……Read the manuals from the controller suppliers. And try to get some explanations from the router machine supplier or google from the internet will be helpful. - 4 G code use

Input the G-code to the machine to run the machine. G code is the actual CNC router language software. It is very basic but easy to learn and very necessary. However, it is no need to write by hand, it is helpful to know the basic commands so you will know what will happen to the machine and why not works correct for the machine. For example, G54 is the working start point. M03 is the spindle off. If necessary, you can modify the program by hand rather than heading back to the CAM software again.

Most of the manufacturing companies are now equipped with the CNC rotuer machines as the market have got very competitive. Hoever, getting the expert labors for operating these machines is becoming quite difficult. Therefore, no matter you want to hunt a new job or fullfil with new technology or escape from the workers limitation, to learn how to use the CNC router machine is a must now and then.