Maintaining a stone engraving machine is essential to ensure its longevity and optimal performance. Regular maintenance can prevent costly repairs and extend the machine’s lifespan. Jinan FORSUN CNC Machinery Co., Ltd. (Shandong FORSUN CNC Machinery Co., Ltd.), one of the leading CNC Router manufacturers in China, has been dedicated to providing high-quality CNC Router Machines and solutions to global customers for 20 years. They offer a variety of CNC machines, including Wood CNC Routers, 3D CNC carving machines, ATC CNC routers, and mini CNC routers. This article will detail the essential maintenance steps to keep your stone engraving machine in excellent condition.

Introduction to Stone Engraving Machines

What is a Stone Engraving Machine?

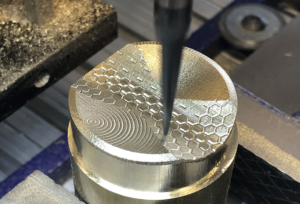

A stone engraving machine, also known as a CNC stone router, is a specialized tool used to carve intricate designs into stone surfaces. These machines are highly valued in industries such as construction, art, and monument making for their precision and efficiency.

Key Components

- Spindle: The main component that rotates the cutting tool.

- Control System: Manages the machine’s operations and movements.

- Cutting Tools: Various bits and blades designed for different types of stone.

- Cooling System: Prevents the machine from overheating during operation.

Why Regular Maintenance is Important

Prevents Downtime

Regular maintenance helps prevent unexpected breakdowns, which can cause significant downtime and delays in production.

Extends Lifespan

Proper care and routine checks can significantly extend the lifespan of your machine, saving money on replacements and repairs.

Ensures Precision

Maintaining your machine ensures it continues to operate with high precision, which is critical for producing quality work.

Safety

Regular maintenance checks also help in identifying and fixing potential safety hazards, ensuring a safe working environment.

Get 500 USD DiscountDaily Maintenance Tasks

Cleaning the Machine

After each use, clean the machine to remove any stone dust and debris. Use a soft brush or cloth to wipe down the surfaces and components.

- Spindle and Collet: Clean the spindle and collet to remove any stone particles that can affect performance.

- Work Surface: Ensure the work surface is clean to prevent any interference with future projects.

Inspecting the Cutting Tools

Check the cutting tools for wear and tear. Replace any dull or damaged tools to ensure precise cuts and avoid damaging the stone.

Lubrication

Lubricate the moving parts of the machine to ensure smooth operation. Use the manufacturer-recommended lubricant to avoid any damage.

Weekly Maintenance Tasks

Checking the Coolant System

Ensure the coolant system is functioning correctly. Check the coolant levels and refill if necessary. Also, inspect for any leaks or blockages.

Inspecting Belts and Gears

Check the belts and gears for any signs of wear or damage. Tighten any loose belts and replace any worn-out gears.

Software Updates

Regularly update the machine’s software to ensure it runs efficiently and benefits from the latest features and improvements.

Monthly Maintenance Tasks

Deep Cleaning

Perform a deep cleaning of the machine. Disassemble the necessary parts to clean hard-to-reach areas. Ensure all components are free from dust and debris.

Alignment Checks

Check the alignment of the machine to ensure it is operating correctly. Misalignment can cause inaccurate cuts and damage to the machine.

Electrical Connections

Inspect all electrical connections for any signs of wear or corrosion. Tighten any loose connections and replace any damaged wires.

Seasonal Maintenance Tasks

Full Inspection

Conduct a full inspection of the machine every few months. Check all components, including the spindle, control system, and cutting tools, for any issues.

Calibration

Calibrate the machine to ensure it is cutting accurately. This involves adjusting the settings and parameters to match the manufacturer’s specifications.

Professional Servicing

Consider having the machine professionally serviced at least once a year. A professional can identify and fix any issues that may not be apparent during routine checks.

Troubleshooting Common Issues

Spindle Overheating

If the spindle overheats, check the coolant system to ensure it is working correctly. Make sure the coolant is flowing properly and the levels are adequate.

Inaccurate Cuts

If the machine is making inaccurate cuts, check the alignment and calibration. Also, inspect the cutting tools for any wear or damage.

Excessive Vibration

Excessive vibration can be caused by loose components or worn-out parts. Check the machine’s belts, gears, and mounting for any issues.

Software Errors

If the machine is experiencing software errors, update the software to the latest version. If the issue persists, contact the manufacturer for support.

Tips for Prolonging the Lifespan of Your Stone Engraving Machine

Proper Training

Ensure all operators are properly trained in using and maintaining the machine. This reduces the risk of user error and damage.

Use Quality Materials

Using high-quality stone and cutting tools can reduce wear and tear on the machine, prolonging its lifespan.

Monitor Performance

Regularly monitor the machine’s performance and address any issues promptly. This helps prevent minor problems from becoming major repairs.

Store in a Clean Environment

Store the machine in a clean, dry environment to prevent dust and moisture from affecting its components.

Introducing Jinan FORSUN CNC Machinery Co., Ltd.

Jinan FORSUN CNC Machinery Co., Ltd. is a leading provider of high-quality CNC machines. With over 20 years of experience, FORSUN offers a wide range of CNC Router Machines designed to meet the needs of various industries.

Get 500 USD DiscountCommitment to Quality

FORSUN is committed to providing reliable and durable machines. Each machine undergoes rigorous testing to ensure it meets the highest standards of performance.

Exceptional Customer Support

FORSUN offers exceptional customer support, including installation, training, and ongoing maintenance services. Their team of experts is always ready to assist with any issues.

Wide Range of Products

FORSUN’s product range includes Wood CNC Routers, 3D CNC carving machines, ATC CNC routers, and mini CNC routers. They have a solution for every need.

Call to Action

For those looking to extend the lifespan of their stone engraving machines, Jinan FORSUN CNC Machinery Co., Ltd. offers the perfect solution. Explore their range of high-quality CNC machines and see how they can enhance your business. Visit FORSUN’s website today to learn more and request a consultation.

Conclusion

Maintaining a stone engraving machine is crucial for its longevity and performance. Regular cleaning, lubrication, and inspections can prevent costly repairs and downtime. By following these maintenance tips, you can ensure your machine continues to operate efficiently for years to come. Jinan FORSUN CNC Machinery Co., Ltd. provides high-quality CNC machines and exceptional support to help you get the most out of your investment. Investing in proper maintenance not only extends the life of your machine but also ensures the quality of your work.