Fiber laser cutting machines have transformed various industries with their precision, efficiency, and versatility. However, for those new to the technology, the thought of training and operating such advanced equipment can be daunting. Jinan FORSUN CNC Machinery Co., Ltd. (Shandong FORSUN CNC Machinery Co., Ltd.), a leading CNC Router manufacturer in China, has been delivering high-quality CNC Router Machines and solutions to customers worldwide for over 20 years. Their range includes Wood CNC Routers, 3D CNC carving machines, ATC CNC routers, and mini CNC routers. This article explores the complexity of training and operating a fiber laser cutting machine, offering insights and practical tips for beginners.

Introduction to Fiber Laser Cutting Machines

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine uses a high-powered laser to cut through various materials with remarkable precision and speed. These machines are widely used in industries such as automotive, aerospace, and manufacturing due to their ability to produce intricate cuts and minimize material wastage.

Key Components

- Laser Source: Generates the laser beam used for cutting.

- Control System: Manages the laser’s parameters and movement.

- Cutting Bed: Supports the material being cut.

- Cooling System: Maintains the optimal temperature of the laser source.

- Assist Gas System: Uses gases like oxygen, nitrogen, or air to aid in the cutting process.

Training: How Difficult is it?

Initial Learning Curve

Basic Concepts

Understanding the basic concepts of laser technology and how a fiber laser cutting machine works is essential. This includes knowledge about laser power, cutting speed, and the types of materials that can be cut.

Software Training

Operating a fiber laser cutting machine requires proficiency in specific software, typically CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) programs. Learning to design and prepare files for cutting is a critical skill.

Hands-On Training

Machine Setup

Training involves learning how to set up the machine, including calibrating the laser, adjusting the cutting bed, and ensuring the material is properly secured. This step is crucial for achieving accurate cuts.

Safety Procedures

Safety is paramount when operating a fiber laser cutting machine. Training includes understanding and adhering to safety protocols, such as wearing appropriate protective equipment, knowing emergency procedures, and maintaining a clean workspace.

Advanced Training

Material-Specific Techniques

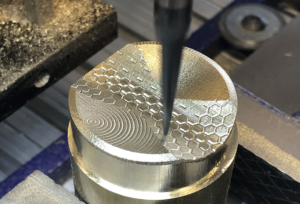

Advanced training covers techniques specific to different materials, such as metals, plastics, and composites. Each material requires different settings and approaches for optimal results.

Troubleshooting

Learning how to troubleshoot common issues, such as laser misalignment, software errors, or material inconsistencies, is an essential part of advanced training.

Operating a Fiber Laser Cutting Machine

Step-by-Step Guide

Loading Material

- Secure Placement: Place the material on the cutting bed and secure it to prevent movement during cutting.

- Leveling: Ensure the material is level to achieve consistent cutting depth.

Setting Parameters

- Tool Selection: Choose the appropriate cutting tool based on the material.

- Laser Settings: Adjust the laser power, speed, and frequency according to the material type and thickness.

- Assist Gas: Select and adjust the assist gas settings to optimize the cutting process.

Starting the Cutting Process

- Run a Test Cut: Perform a test cut on scrap material to ensure settings are correct.

- Monitor the Process: Keep an eye on the cutting process to ensure everything runs smoothly and make adjustments as necessary.

Common Challenges and Solutions

Material Handling

Different materials react differently to laser cutting. Understanding how each material behaves under the laser is crucial for achieving high-quality cuts.

Maintenance

Regular maintenance is required to keep the machine in optimal working condition. This includes cleaning the laser lens, checking the cooling system, and ensuring all moving parts are lubricated.

Software Updates

Keeping the software updated ensures compatibility with the latest features and improvements, enhancing the machine’s performance.

Tips for Beginners

Start with Simple Projects

Begin with simple designs to build your confidence and understanding of the machine. Gradually move on to more complex projects as you gain experience.

Seek Professional Training

Enroll in professional training courses offered by the manufacturer or certified training centers. These courses provide comprehensive instruction and hands-on experience.

Join Online Communities

Participate in online forums and communities where you can share experiences, ask questions, and learn from other users.

Regular Practice

Spend time regularly practicing on the machine to hone your skills and become more comfortable with its operation.

Jinan FORSUN CNC Machinery Co., Ltd.: Your Partner in Laser Cutting

Commitment to Quality

Jinan FORSUN CNC Machinery Co., Ltd. is committed to providing reliable and durable machines. Each machine undergoes rigorous testing to ensure it meets the highest standards of performance.

Exceptional Customer Support

FORSUN offers exceptional customer support, including installation, training, and ongoing maintenance services. Their team of experts is always ready to assist with any issues.

Wide Range of Products

FORSUN’s product range includes Wood CNC Routers, 3D CNC carving machines, ATC CNC routers, and mini CNC routers. They have a solution for every need.

Call to Action

For those looking to enhance their manufacturing capabilities, Jinan FORSUN CNC Machinery Co., Ltd. offers the perfect solution. Explore their range of high-quality CNC machines and see how they can support your business. Visit FORSUN’s website today to learn more and request a consultation.

Conclusion

Training and operating a fiber laser cutting machine can initially seem challenging due to the technical knowledge and skills required. However, with proper training, practice, and support from reliable manufacturers like Jinan FORSUN CNC Machinery Co., Ltd., the process becomes manageable and rewarding. Investing in the right equipment and training will not only enhance your business operations but also ensure long-term success in a competitive market.