When you think of CNC router machines, you usually think of plastic and wood. People often ask whether CNC router machines can cut aluminum. The answer is “Yes, any CNC router machine can cut aluminum.”

What is The Best CNC Router for My Business?

Can A CNC Router Cut Aluminum?

Is a CNC Router Easy to Cut Aluminum?

When most people think of machining metals such as aluminum, they think of high-end router machines. Such a machine can perform extremely complex tasks, and its spindle rotates cutting tools at a speed comparable to most high-speed drills.

Most CNC router machines should be able to use CNC machines to process aluminum. By matching the material to the right end mill head and feed speed, you can cut aluminum easily.

At the same time, you will find that machining aluminum with CNC router machines not only saves time and effort but also has high productivity.

What Are The Best CNC Router Bits For Aluminum?

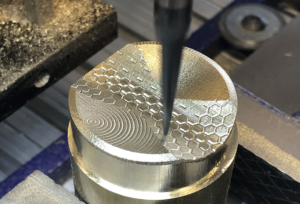

CNC router tools for aluminum use a special proprietary trimming system, high-quality sub-micron carbide, and have ultra-high polished cutting edges, which can achieve neat cutting, excellent surface finish and longer The service life of CNC tools.

CNC Aluminum Router Project

Work Video of Cutting Aluminum

Click Here to Get the Best Price!

Tips For Cutting Aluminum Using CNC Router

Your CNC router can cut through acrylic and wood just fine, but How to cut aluminum using a CNC router? Here are 9 tips to make sure you do it right:

-

Fixing Material

Even if you will use a small CNC router machine for very light cuts, there will still be a lot of friction and stress on the cutting spindle and the gantry of the fixed router machine. Every part of the machine will be under tremendous pressure. You must install materials, router planers, and cutting tools in the strictest way.

The less the machine moves relative to the cutting path, the better the quality of the part. The way of fixing the material is essential for any type of CNC machine, but this is especially important when cutting aluminum with a CNC router machine. You want to avoid movement between the cutting tool and the material as much as possible.

-

Machining Aluminum With Carbide End Mills

CNC router machines usually use different special tools, which should not be used with aluminum. The knives you need should be made exclusively of aluminum. This helps to increase the recommended rpm to ensure that your router cutter is satisfied when running the CNC router machine spindle at high speeds.

Click Here to Get the Best Price!

-

Use Smaller Diameter Tools

Using a smaller diameter tool will increase the speed. Reduce it to 1/4, in case of deflection, use a rigid cutter. Remember that carbide router cutters are much harder than HSS.

-

Use The Feed And Speed Calculator

Cutting aluminum with a CNC router machine is not easy. All CNC can simplify life with feed and speed calculator.

–Minimum RPM setting

-CNC router cutter type: make sure the new calculator has a V position, compression position, and reduction position.

-Deflection: Ensure that your calculator can measure deflection and provide solutions to avoid excessive deflection

-

Drills With Fewer Grooves Make More Sense

When you cut aluminum, large chips are generated. You can’t solve this problem. However, you can use 3 flutes or less. This leaves more space between the cutting edges and provides a larger blow-off space for large chips.

The fewer grooves, the better. If you have 4 or more flutes, chips will clog your flutes and your drill will break.

Click Here to Get the Best Price!

-

Pay Attention To The Depth Of Cut And Groove

The more you cut, and the closer to the groove where the cutter enters, the more difficult it is to remove the chips from the bottom of the hole. Do more passes to reduce to the desired depth, and turn on shallower depths for better access.

-

Don’t Reduce The Feed Rate Too Slowly

Too slow feed rate may cause tool friction instead of cutting. Compared with router machine users, CNC router machine users are at greater risk because the spindle almost always runs very fast. In order to keep the recommended chip load at a high rpm, the cutter must be kept moving relatively quickly.

-

Lubricate With Mist

In order to reduce the sticking of chips on the cutting edge, a suitable lubricant must be used. Assuming that you have been hit by compressed air so far, running a coolant mist in the same mechanism is not a bad idea. A useful and inexpensive option can be a sprayer, which can be used to provide blast while also acting as a coolant. If you want to cut shallow passes or cut very thin aluminum, you can eliminate lubricants.

-

Never Worry

CNC router machines may be slower, but they can still be used for more materials than most CNC router machines. Relax and let the machine do the work.

With these tips in mind, you can now cut aluminum and reduce a lot of frustration. Next time you use a CNC router machine to cut aluminum, please check it, learn from it, and improve your ability to cut aluminum.

Best CNC Routers For Aluminum 2020

There are many types of CNC router machines for aluminum processing. How to choose a suitable CNC router machine for aluminum? Everything depends on your requirements.

- 2020 Best Automatic Tool Change CNC Router FS1530ATC for Sale

The CNC router FS1530ATC is a highly configured CNC router machine. It is widely used for high-speed cutting, drilling, and milling of various plates. This is a high-performance CNC cutting machine with a flexible configuration to meet the needs of various processing applications. The main application of the Router CNC is the processing of aluminum panels, furniture panels, composite materials, PVC, and engineering plastics.

- Best 4 Axis Wood CNC Router FS1325D-4Axis

The four-axis linkage engraving machine adopts the industrial control system four-axis linkage control, with excellent and stable quality, good maintenance, and usability, and can control the 3D machining of the cylinder and the rotation of the tetrahedron.

Click Here to Get the Best Price!

- Light-Duty 5 Axis CNC Wood Router Machine

The mini 5 Axis Router Machine has a small footprint and complete functions. The most important one is the programming simulation processing software, which can be used by students for practical operation and bold operation. No need to worry about machine failure. Many university laboratories introduced the teaching research of this machine tool, which was obtained from the actual operation.

Go to relevant data to conduct theoretical research in a better and more scientific way.

Best CNC Router For Aluminum Buying Guide

How to Buy an Affordable CNC machine for Aluminum? Among all available models, it is not easy to choose the right model according to your needs. This buyer’s guide will guide you through all the steps to purchase a machine that meets your needs.

-

Motor Size

Servo motors are an ideal choice for a high-speed operation that requires continuously changing loads and provides high torque capabilities. They are very efficient and do not make too much noise during operation. The motor will not heat up.

On the other hand, the stepper motors are cheap. Their movement is based on pulses and does not receive feedback from the actual position. They operate in low to medium speed and high torque applications and are also easy to set up and operate.

The stepper motor has a long life because any overload will not damage the motor. However, when the motor is set to medium to high-speed performance, it will be very loud.

No matter which type of motor you choose, it is worth choosing a CNC router machine that can run efficiently and requires minimal supervision.

Click Here to Get the Best Price!

-

Automatic Tool Change System

ATC changes tools very quickly, thereby reducing the cycle time of tool operations.

If you are considering investing in a CNC router machine because you are a business and considering changing tools occasionally during the production process, one way to solve this problem is to obtain an automatic tool change system. This minimizes operator errors and reduces the time between operations.

On the other hand, if your interest in the CNC router machine is more of a hobby, and you only really need to use one tool at a time, then the logo of the CNC router machine may be able to meet your requirements. In this case, there is no need to obtain the automatic tool change function.

In addition, having some understanding of the functions of CNC router machines, so that investment in updated software will regularly produce accurate cuts and updates.

If your company produces complex components, you may want to consider acquiring specialized software.

-

Spindle

The spindle is a motor that performs cutting with a cutting tool. They come in many shapes and sizes. Factors such as application and cycle time will allow you to make even bigger cuts.

Before investing, it is best to investigate the capacity of the spindle. This will involve inspections such as power requirements, spindle motor type, torque, etc.

-

Router Size

It would be wise to consider the size of the CNC router machine by considering current and future production. This is especially true if you are a small business because you will want to make sure not to restrict production just because the CNC router machine cannot handle larger materials.

In the end, the best decision that can be made for your business is to choose a CNC router that will provide you with enough room for expansion without the need to completely purchase another CNC router machine.

Click Here to Get the Best Price!

-

Dust Collection

The CNC router machine produces a lot of wood chips. If not properly controlled, it will adversely affect other machine parts. Therefore, it is important to remove the dust regularly. Vacuum systems are convenient because they can effectively clean the entire operating area. You can also use a dust collector. However, the two are functionally different. The vacuum system has high precision and can work on the basis of high pressure and low flow, while the dust collector is usually the opposite. Choose one according to the amount and type of dust generated.

-

Easy To Serve

Familiarize yourself with the brand you are buying and make sure to buy a brand with excellent customer service. It is also important to provide service and support on the machine and to replace it later.

-

Price-quality Ratio

To buy a high-quality CNC router, you have to spend a lot of money. The quality of function, brand, size, and various other factors also determine the price. Before buying one, keep all these factors in mind and don’t exceed the maximum amount you can afford.

Almost all types of routers can use CNC routers on aluminum. Through a clever selection of cutting and processing parameters, the machine’s capacity is matched to the optimal speed and meets the aluminum feed requirements. Contact us to learn more about the CNC router for aluminum.