2025 CNC Water Jet Cutting Machine for Stone and Metals

2025 CNC Water Jet Cutting Machine for Stone and Metals offers exceptional precision and versatility for cutting a wide range of materials, including marble, granite, steel, and other metals. Equipped with advanced CNC control, it ensures accurate, clean, and intricate cuts without thermal effects, preserving the integrity of the materials. Ideal for industrial use, this high-performance water jet cutting machine is perfect for both large-scale production and custom projects, delivering reliable results across various stone and metal cutting applications..

2025 CNC Water Jet Cutting Machine for Stone and Metals – Configuration

The 2025 CNC Water Jet Cutting Machine is designed with advanced features to ensure precision and efficiency in cutting a variety of materials, including stone, marble, granite, and metals. Key configurations include:

-

High-Pressure Water Pump: Capable of delivering up to 60,000 psi for precise cutting with minimal material waste.

-

CNC Control System: User-friendly interface with advanced software for easy setup and operation.

-

Cutting Head: Equipped with a precision cutting head that ensures clean and accurate cuts across multiple materials.

-

Heavy-Duty Frame: Robust steel frame designed for stability and durability during high-performance cutting.

-

Material Compatibility: Suitable for cutting hard materials such as granite, marble, steel, aluminum, and more.

-

Water Filtration System: Ensures clean cutting and extends the life of the machine by filtering out debris.

This configuration is ideal for industries requiring high precision and versatility in cutting complex designs across stone and metal materials.

Machine Video

Application of 2025 CNC Water Jet Cutting Machine for Stone and Metals

The 2025 CNC Water Jet Cutting Machine is highly versatile and suitable for a wide range of industrial applications, including:

-

Stone and Marble Cutting: Ideal for precise cutting of intricate designs in stone, marble, and granite for construction, decorative, and architectural applications.

-

Metal Cutting: Capable of cutting various metals such as stainless steel, aluminum, and titanium, making it perfect for industries like aerospace, automotive, and manufacturing.

-

Architectural Design: Used for creating detailed patterns and shapes in stone and metal for interior and exterior design projects.

-

Signage and Branding: Ideal for cutting materials used in the production of custom signage and branding elements.

-

Custom Fabrication: Provides flexibility in producing custom-cut parts, prototypes, and unique designs for industries requiring precision work in stone and metals.

This machine is essential for businesses that require high-precision cuts in stone and metal materials, providing versatility for both small-scale and large-scale production.

Suitable Materials for 2025 CNC Water Jet Cutting Machine for Stone and Metals

The 2025 CNC Water Jet Cutting Machine is designed to handle a wide variety of materials with precision and efficiency, including:

-

Stone: Marble, granite, limestone, and slate, ideal for both intricate designs and large-scale cuts.

-

Metals: Stainless steel, aluminum, titanium, brass, and copper, offering clean, precise cuts without heat distortion.

-

Glass: Tempered glass, laminated glass, and other specialty glass types, suitable for custom cutting and detailed patterns.

-

Ceramics: Porcelain, tile, and other ceramic materials, ideal for intricate designs and custom fabrication.

-

Composites: Carbon fiber, fiberglass, and other composite materials, commonly used in industries like aerospace and automotive.

-

Plastics: Acrylic, PVC, and other plastic sheets, perfect for signage, decorative pieces, and custom parts.

This machine provides exceptional versatility, offering the ability to cut a broad range of materials with high accuracy, making it ideal for various industries such as construction, automotive, manufacturing, and art.

Parameter Data of Saw Blade and Spindle Bridge Saw Cutting Machine

| Model Name | FS2030 |

| X, Y-Axis Travel | 2000*3000mm(4*8ft), Optional: 1300X3000mm(4X10ft), 1500X3000mm(5X10ft), 2000X3000mm. 2000X4000mm. |

| Z-Axis Travel | 200, Optional: 300mm,400mm, 500mm,600mm. |

| Spindle Power | 5.5KW Marble engraving spindle with 24000RPM. ER25 |

| Drive System X, Y, and Z-axis | German Helical Rack and Pinion for X and Y-axis. And Z-axis with TBI ball screw |

| Transmission X, Y, and Z-axis | HIWIN/THK Rail Linear guide and bearings. |

| Motor for X, Y, and Z | Stepper motor / AC Servo motor |

| Machine Structure | Thicken weld steel tube machine body. Rigid cast steel gantry and side support and table, water tank |

| Working Voltage | 220V/50HZ/60HZ,3PH or 380V/50HZ/60HZ,3PH |

| Command Language | G Code & M Code |

| Operating System | DHTN PC Controller system |

| Collet | ER25, φ4, φ6,1/8, 1/2 |

| Lubrication | Automatic lubrication system |

| Tool Calibration | Automatic tool sensor |

| Max. Rapid Travel Speed | 40000mm/min |

| Max. working Speed | 25000/min |

| Repeatability | +/-0.04mm/300mm |

| Working Accuracy | +/-0.03mm/300mm |

| Machining Function | 2D Machining, 2.5D Machining, 3D Machining |

| Compatible Software | Type3, Ucancam, Artcam, etc. |

| Other Names | marble engraving machine, marble carving machine, marble router machine, CNC marble engraving machine, granite marble cutting machines, marble stone cutting machine, marble engraving tools, CNC stone router machine |

| Suitable Materials &Applications | Marble, bluestone, jade crystal, agate, glass, plastic cement, ceramic, stainless steel, titanium, copper, iron, aluminum, bamboo, and other hardwood surfaces of virtue and sculpture. |

| Gross Weight | 2000 KGS |

| Package Size | 3900*2250*1950mm |

Machine Pictures of Saw Blade and Spindle Bridge Saw Cutting Machine

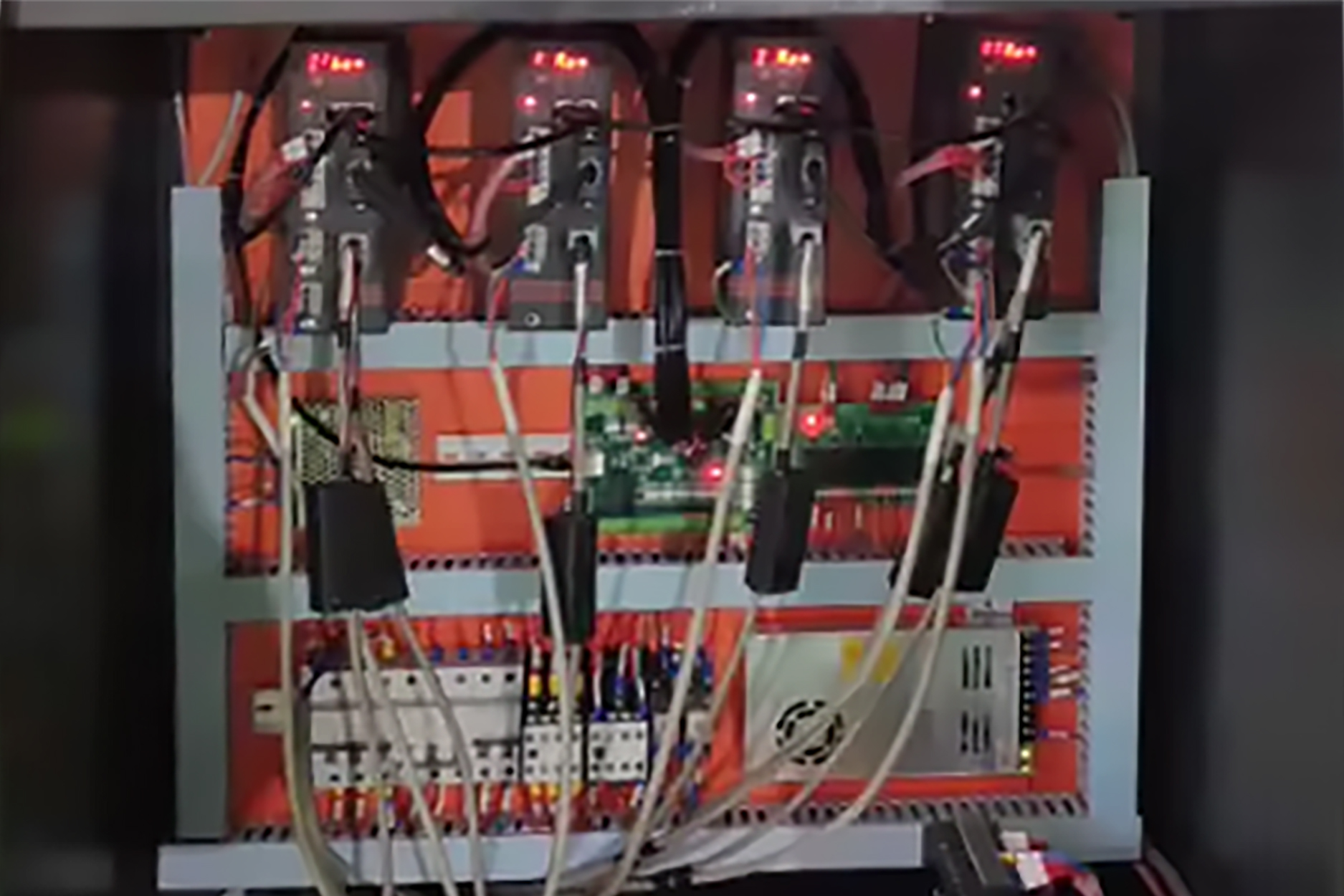

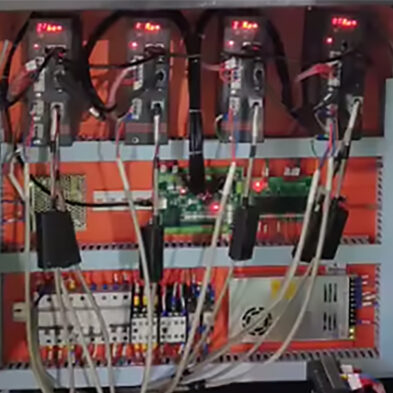

Control cabinet

Computer

Marble cutting saw

80°adiustable table

Dust cover

Wood table

Projects by Saw Blade and Spindle Bridge Saw Cutting Machine

Maintenance of 2025 CNC Water Jet Cutting Machine for Stone and Metals

Proper maintenance is crucial for ensuring the long-lasting performance and efficiency of your 2025 CNC Water Jet Cutting Machine. Here are key maintenance guidelines:

-

Daily Checks:

-

Inspect the water level and ensure it is at the recommended level.

-

Check for any debris or blockages in the cutting head and water jet nozzle.

-

Clean the filtration system to prevent clogs and maintain optimal water pressure.

-

-

Weekly Maintenance:

-

Examine the cutting head and replace any worn-out parts like nozzles or abrasive tubes.

-

Inspect the pump for any signs of wear and tear, and check for any unusual vibrations or noises.

-

Clean the tracks, rails, and other moving parts to ensure smooth operation.

-

-

Monthly Maintenance:

-

Check the machine’s electrical components for any loose connections or potential issues.

-

Test the software and control systems for proper calibration and software updates.

-

Perform a thorough cleaning of the water tank and check for any sediment buildup.

-

-

Annual Maintenance:

-

Replace the high-pressure seals and O-rings to prevent leaks and maintain high water pressure.

-

Perform a complete system calibration to ensure cutting accuracy.

-

Inspect the CNC controller and replace any outdated software or hardware components.

-

By following these maintenance procedures, your 2025 CNC Water Jet Cutting Machine will remain in peak condition, providing consistent and reliable performance for cutting stone, metals, and other materials. Regular maintenance helps extend the life of the machine and minimizes the need for costly repairs.

Why Choose Us?

- Professional CNC Router factory with more than 10 years experience in CNC Router design, manufacture, machining, inspection, etc

- All the spare parts are a world-famous brand like Siemens controller from Germany, Yaskawa servo motors from Japan, Igus cable from Germany, ABB from Switzerland, and so on.

- All the machine bodies are through whole welding, heat treating, sandblasting and three times painting to make sure the machine body will be never out of frame or painting problem. It will make your machine always work in high precision, fast speed like the new machine.

- 7*24 hours service after the sale with English, Russia, Spanish or Portuguese, etc.

- 3 years warranty for main spare parts while easy broken parts are 1.5 years.

Feel free to contact us if you have any questions about our CNC Routers. We’re on GMT +8 and reply to all emails within 12 hours.

Reviews

There are no reviews yet.