Multi Spindle CNC Router | Multi Head CNC Router

Multi head CNC router (Multi spindle CNC router) is a wood CNC machine that mainly designed for users who need to manufacturing large quantities of standardized small size products. This CNC machine’s multiple spindles can be customized and processed simultaneously to meet the needs of batch processing of products.

The multi head CNC router is used in machining three-dimensional wave board, cabinet & solid wood doors, craft & paint-free wooden doors, and windows, relic furniture, luxurious European furniture, oriental furniture, American, and any form of African furniture. And it is also appropriate for processing doors, embossed art screens & craft gifts, craft windows, solid wood art murals, woodwork calligraphy carving, art photo frames, electrical countertops, sports equipment carving, violin & piano arcs, non-ferrous metal carving and cutting art murals, woodwork calligraphy carving, art photo frames, electrical countertops, sports equipment, violin arcs, non-ferrous metal carving and cutting.

Before your order, you need to know that the Multi-process CNC Engraving Machine and Multi Spindle relief CNC engraving machines are different types of Multi Spindle CNC router with different functions.

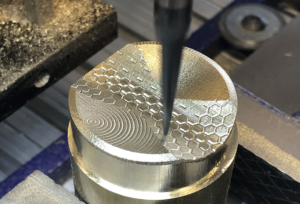

The multi-process CNC Router machine is a CNC Engraving Machine that can process multiple works by different spindles. The spindles of this CNC Router Machine can change automatically. Mostly, the spindles of this CNC wood router can be 2-4 sets. Each spindle can be equipped with different cutting tools. These different processes can not be carried out at the same time by automatic tool change technology. The performance of the multi-process CNC router is good and the precision is high. The applications of this multi-process spindles CNC router are wooden doors, sliding doors, soft-packed doors, solid wood furniture, solid wood doors, hollowed out the grid, and so on.

The multi-head relief CNC Router Machines are equipped with the same spindles on the Z-axis. This Multi Spindle CNC Router is built to increase working efficiency. The working principle of a Multi Head CNC engraving machine is very simple. Multiple working spindles work at the same time with the same running path. Thus the processing rate is doubled.

Other hot CNC machine collections: wood CNC machine, 4 axis CNC router, 5 axis CNC router, CNC plasma cutter, stone CNC router, ATC CNC router, mini CNC router