Introduction

In the metal fabrication industry, precision and efficiency are crucial for maintaining high-quality production. Fiber laser cutting machines have revolutionized steel plate and tube processing, offering unparalleled accuracy, speed, and cost-effectiveness. Whether in industrial manufacturing, construction, or custom metalworking, fiber lasers have become the go-to solution for cutting various thicknesses of steel plates and tubes with superior edge quality and minimal waste.

This article explores how fiber laser technology enhances steel cutting efficiency, its key advantages, and essential tips for optimizing your cutting process.

Why Choose Fiber Laser for Steel Plate and Tube Cutting?

1. High Cutting Precision

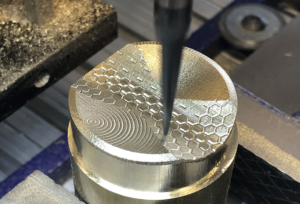

Fiber lasers provide extreme accuracy in cutting both flat steel sheets and round/square tubes. With narrow kerf width and minimal heat-affected zones (HAZ), these machines ensure clean edges, reducing the need for secondary processing.

Control handle

Control System

Large diameter chuck

Laser Head

Rotary axis

Servo Motor

2. Versatile Material Compatibility

Fiber laser technology supports a wide range of steel materials, including:

- Carbon steel – Achieves clean cuts with high-speed processing.

- Stainless steel – Ensures smooth edges with no oxidation.

- Galvanized steel – Cuts efficiently while minimizing material distortion.

3. Enhanced Efficiency & Speed

Compared to traditional plasma or CO₂ laser cutters, fiber lasers offer faster cutting speeds, improving productivity and reducing production time. The automated CNC system further enhances efficiency by optimizing cutting paths and minimizing material waste.

4. Cost-Effective and Low Maintenance

Fiber lasers are known for their low operational costs, as they consume less energy and have longer-lasting laser sources compared to CO₂ lasers. The non-contact cutting method also reduces wear and tear, leading to minimal maintenance requirements.

5. Tube and Plate Integration

Modern fiber laser machines can cut both steel plates and tubes in a single system, allowing manufacturers to handle diverse cutting tasks without switching machines. This integration streamlines production and maximizes space utilization in workshops.

How to Optimize Fiber Laser Cutting for Steel?

1. Choose the Right Laser Power

- 1-3kW for thin steel plates (≤5mm).

- 3-6kW for medium-thickness steel (5-12mm).

- 6kW+ for thicker steel plates and heavy-duty cutting.

2. Optimize Cutting Speed and Gas Pressure

- Higher cutting speeds improve efficiency but may reduce cut quality if set too fast.

- Oxygen (O₂) is ideal for carbon steel, while Nitrogen (N₂) prevents oxidation on stainless steel.

3. Maintain Lens and Nozzle Cleanliness

- Regularly clean and inspect optical components to avoid beam distortion.

- Check and replace nozzles to ensure precise gas flow for smooth cuts.

4. Utilize CNC Automation

- Use advanced CAD/CAM software for precise nesting and material utilization.

- Enable real-time monitoring to adjust parameters for optimal results.

5. Implement Proper Cooling and Ventilation

- Ensure a stable cooling system to prevent overheating and extend machine lifespan.

- Effective ventilation systems help remove fumes and improve workplace safety.

Applications of Fiber Laser Cutting for Steel

Fiber laser cutting is widely used in industries such as:

✅ Metal Fabrication – Producing precision steel components.

✅ Automotive Manufacturing – Cutting chassis, exhaust systems, and structural parts.

✅ Construction & Architecture – Creating custom metal structures and facades.

✅ Aerospace – Fabricating lightweight, high-strength steel components.

✅ Machinery & Equipment Manufacturing – Cutting parts with tight tolerances for industrial machinery.

Conclusion

Fiber laser technology has transformed the way manufacturers cut steel plates and tubes, providing unmatched precision, efficiency, and cost savings. By choosing the right laser power, optimizing cutting settings, and maintaining the equipment properly, businesses can maximize productivity and reduce material waste.

Looking for a high-performance fiber laser cutting machine for your steel processing needs? Contact us today to find the best solution for your business!