Our ATC CNC woodworking router machines are carefully designed and manufactured to meet your application and budget requirements. All of our CNC milling machines are durable, reliable, and have excellent customer support. The ATC CNC router machine is a CNC machine tool with an automatic tool change spindle, vacuum table, dust collector, automatical lubrication system, safety laser light bar which protects the safety of the operator. The CNC router tool can automatically change the CNC router ATC work according to the work needs, without manual operation, which will greatly improve work efficiency.

What is The Best CNC Router for My Business?

Features of ATC CNC Woodworking Router

Forsun new ATC CNC Router excels at delivering unparalleled cut quality and consistency. With humanized design, even for the most beginner CNC Router Machine user can be operating a new CNC Wood Router in just days, not weeks. This Wood CNC Router is mainly designed for the panel processing sector, it also excels at machining plastic and non-ferrous metals. This smart ATC CNC Router is ideal for those workshops that are looking to produce the maximum number of orders with quick and reliable delivery times.

- 12HP HSD Spindle, ISO 30,24000RPM, ER32

- 1000W AC Servo Motors

- Smart NC Studio Controller

- Linear Automatic Tool Changer with 10 pcs positions.

- Safety laser light bar

- Vacuum table in zones

- Auto lubrication system

- Dust collector system

- The automatic pin location device

- 380V 3PH or 220V, 3 Phase

Applications of the ATC CNC Wood Router Machine

This CNC Router Machine was made especially for industries such as Foam mold making, Cabinet-making, plastic sheeting processing, and sign making, aluminum cutting, etc.

- Woodworking:

Solid wood doors, kitchen cabinets, wardrobes, tables, beds, computer desks and cylinders, table legs, wooden crafts, painted doors, screens, hand fan windows, etc. - Advertising:

Advertising signs, sign production, acrylic cutting, plastic molding, production of advertising decoration products of various materials. - Mold industry:

Carving wood, foam, EPS, copper, aluminum molds, and non-metallic molds such as artificial marble, plastic cloth, PVC pipe, wood, etc.

Suitable Material of Linear ATC CNC Woodworking Router

- Wood: Plywood, Soft Wood, Hard Wood, MDF, Chipboard

- Plastic: Acrylic, ABS, HDPE, PVC, UHMW, HDPE

- Stone: Granite, Marble, Slate, Basalt, Pebbles, Natural Stone, Ceramic, Porcelain

- Soft Metal: Aluminium, Brass, Copper, Mild Steel

- Composite: Aluminium Composite, Copper Composite, Titanium Composite, Zinc Composite.

Machine Video of ATC CNC Router Machine

ATC Wood Cutting Machine Projects Gallery

Parameter Data of ATC CNC Wood Router Machine

| Model Name | Good Quality Linear ATC CNC Woodworking Router Machine |

| X, Y-Axis Travel | 1500X3000mm(5X10ft), Option:2000X3000mm. 1300X2500mm(4X8ft), 2000X4000mm |

| Z-Axis Travel | 200mm, Option: 300mm,400mm,500mm,600mm |

| Spindle Power | 9.0KW ATC Spindle with 24000RPM, ISO30, ER32 |

| Auto Pusher | Auto Pusher (optional) |

| Tool Magazine | Linear Automatic Tool Change with 10 pcs positions Tool Magzine. Option: carousel type Auto tool changer magazine |

| Motor for X, Y, and Z | 1000W AC Servo motor |

| Operating System | NC Studio Controller Option: Syntec controller. SIEMENS Controller, DSP |

| Drive System X, Y, and Z-axis | Helical Rack and Pinion for X and Y-Axis, High precision ball screw for the Z-axis. |

| Transmission X, Y, and Z-axis | HIWIN/THK Rail Linear guide and bearings. |

| Machine structure | Cast steel table structure and side support, aluminum T-Plate Extrusion Combined vacuum table |

| Working Voltage | 220V/50HZ/60HZ,3PH 380V/50HZ/60HZ,3PH |

| Command Language | G Code & M Code |

| Collet | ISO30,φ4,φ6,1/8,1/9 |

| Lubrication | Automatic lubrication system |

| Tool Calibration | Automatic tool sensor |

| Dust collector system | 3.0KW Dust collector system with 2 bags |

| Max. Rapid Travel Speed | 80000mm/min |

| Max. working Speed | 45000/min |

| Repeatability | +/-0.04mm/300mm |

| Working Accuracy | +/-0.03mm/300mm |

| Other Names of the CNC Router | CNC Wood Router, CNC Router Machine, Router Machine, Wood CNC Machine, CNC Cutting Machine, CNC Wood Carving Machine, CNC Engraver, 3 axis CNC Router, Best CNC Router, CNC Router Price, Wood Router, Wood CNC Router, 3D CNC Router, Router CNC, Aluminum CNC Router. CNC Engraving Machine, CNC Milling Machine, CNC Drilling Machine, Best CNC Router, 4×8 CNC Router, Cheap CNC Router, CNC Carving Machine, China CNC Router, 3d Wood Carving Machine. |

| Machining Function | 2D Machining, 2.5D Machining, 3D Machining |

| Compatible Software | Type3, UcancCAM, ArtcCAM, AlphCAM, Vectric, Enroute, MasterCAM Cabinet Vision, etc |

| Gross Weight | 2500 KGS |

| Package Size | Plywood Package 4000*2250*1900mm |

CNC Router Machine Gallery

Italy HSD Spindle

HSD provides a variety of electric heads and milling electric spindles for metal and composite alloy processing, with a wide range of power and working speed, and high reliability.

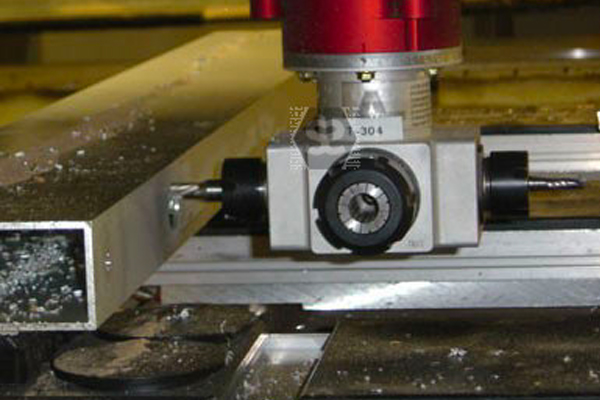

Linear ATC

Linear Tool Magazine with 10 cutting positions, option 12 pcs.

NC Studio System

The NC Studio system is a reliable and cost-effective motion control system for CNC milling machines. Widely used in 3D CNC engraving machine, woodworking engraving machine, stone engraving machine, etc.

Tool Sensor

Tool sensor is suitable for CNC machine tools and CNC tools, and are used to detect the position of cutter blades.

T-slot+Vacuum Table

The T-slot vacuum table can absorb very small pieces of material.

Working Hours Meter

Highly reliable count up/down hour meters.

Optional Device for ATC CNC Router

1, Wood Duo Aggregate

The woodworking duo aggregates designed for the Wood Line electro spindles allow a wide range of machining operations to be carried out, including milling, boring and cutting.

2, Rotary Axis (The 4th Axis of CNC Router / 4 Axis CNC Router)

The application of the Rotary Axis CNC Router is cylindrical or 3D sculptures in stone, woodworking, advertising, metal, and other industries. We can build the Rotary Axis CNC Router. At the same time, the rotary shaft device can also be added to the standard CNC Router to realize the cylindrical engraving working. Thus, round material and flat material can be processed in one CNC Router. It will save a lot of time and improve high efficiency.

3, Safety Laser Curtain / laser barriers to Proect Operator

We suggest installing laser barriers to create laser safe temporary work areas. It is designed to enable operators to work in complete safety. When you need maximum flexibility for enclosing a laser work area or need a temporary Class 1 laser safe work zone, choose movable laser barriers. Movable barriers are a great alternative to laser curtain systems.

Why Choose Forsun CNC Router Machine?

Thicken weld tube machine frame for high performance and material processing.

Heavy duty frame milling and drilling by machining center to keep high accuracy.

Sandy blasting putty and rusty cleaning before painting to prolong machine body use.

Material incoming inspection to make sure machine quality in the very beginning.

During the CNC Router installation process, precision instruments are used to ensure the accuracy of the CNC Router Machine installation.

After the CNC Router is installed, use the testing instrument to test the Vertical accuracy, traveling accuracy, working accuracy, repeated positioning accuracy, etc.

Vui Tinh –

FS1325 CNC ROUTER Machine is a great idea And worth the money for money .The spindle power is very high, which greatly improves the work efficiency。The vacuum table also helped a lot。so good!!!!!!