Water jet cutting technology has revolutionized the way industries cut tough materials like marble, stone, and steel. By using a high-pressure stream of water, often combined with abrasives, water jet cutting machines provide precision cutting without compromising material integrity. Whether you’re in the stone, steel, or marble industry, understanding how to effectively use a water jet cutting machine is crucial for achieving high-quality cuts.

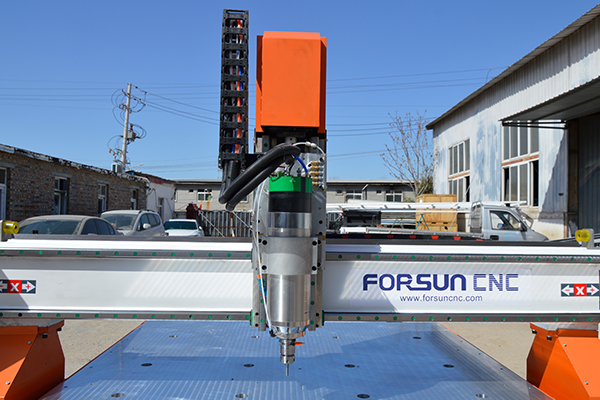

Jinan FORSUN CNC Machinery Co., Ltd. (Shandong FORSUN CNC Machinery Co., Ltd.), one of the leading Wood CNC Router manufacturers and suppliers in China, has been at the forefront of CNC machinery for over 20 years. With a focus on high-quality machines, including Wood CNC Routers, 3D CNC Carving Machines, and more, FORSUN has consistently delivered reliable CNC solutions to customers worldwide. This extensive experience assures our customers that the information you will find here is trustworthy and proven in the industry.

Introduction to Water Jet Cutting Technology

Water jet cutting machines use a fine, high-pressure jet of water (sometimes mixed with abrasives) to cut through a wide variety of materials. They are extremely versatile, capable of cutting everything from soft materials like rubber and plastics to tough materials like steel and marble. The process is precise, clean, and ideal for industries where intricate cuts and delicate materials are involved.

Unlike traditional cutting methods that may generate heat, water jet cutting remains cold, preventing thermal distortion of materials. This makes it particularly suitable for cutting sensitive materials like marble, granite, and steel, where heat could alter the material properties or cause cracks.

Why Choose Water Jet Cutting for Marble, Stone, and Steel?

Water jet cutting offers several advantages over other cutting methods, especially for materials like marble, stone, and steel. Here are some of the key reasons why this technology is preferred:

-

No Heat-Affected Zones: Water jet cutting does not produce heat, which is critical when working with materials like stone or marble that are sensitive to thermal damage. In contrast, methods like laser cutting or plasma cutting can lead to heat-affected zones that damage the material.

-

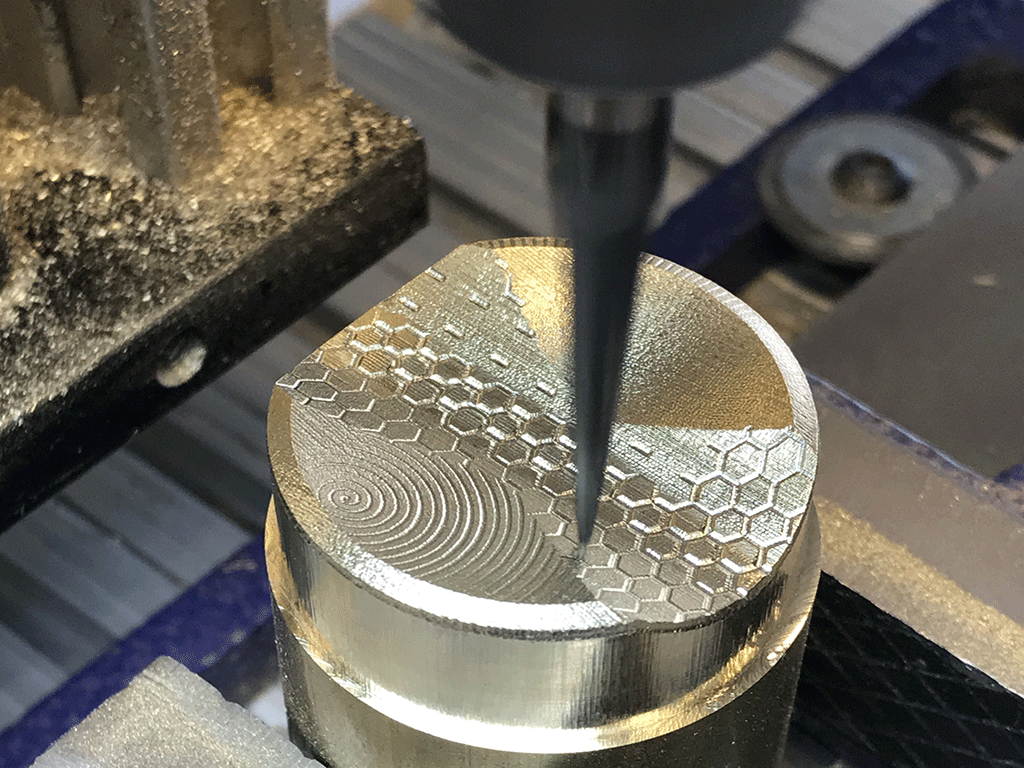

Precision and Accuracy: Water jet machines can achieve high levels of precision and accuracy, with cuts as fine as 0.1mm. This is ideal for intricate designs or when precision is essential for the final product.

-

Clean Edges: Since water jet cutting doesn’t involve contact with the material, it produces smooth, clean edges, reducing the need for further finishing. This is especially beneficial for marble and stone, where rough edges would detract from the material’s natural appearance.

-

Environmental Considerations: Water jet cutting is environmentally friendly, producing minimal waste. The use of water as the cutting medium also means there is less dust, making it safer for operators and the environment.

control-system

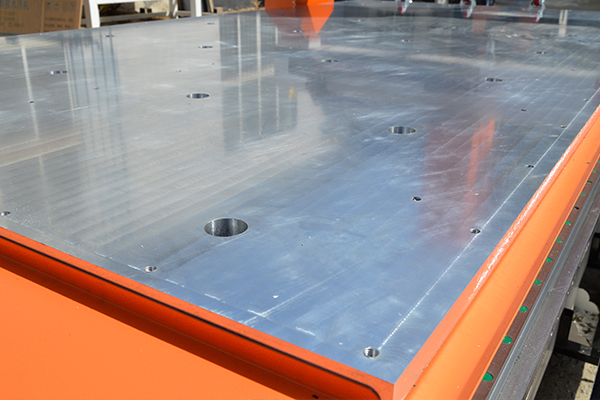

Aluminum-Table

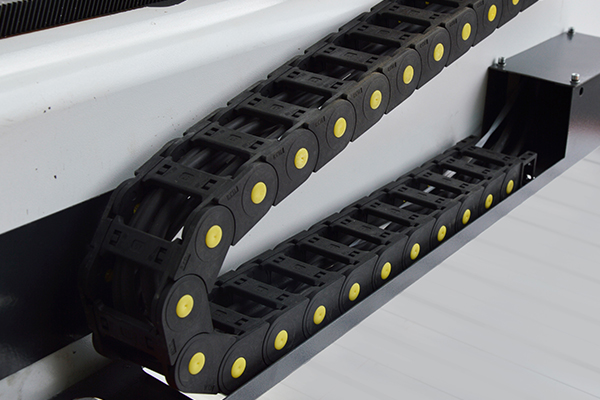

drag-chain

Loading-unloading-wheel

Oil-mist-cooling

water-cooling-spindle

How Does a Water Jet Cutting Machine Work?

Understanding the operational procedure of a water jet cutting machine is essential for maximizing its effectiveness when cutting marble, stone, and steel.

Step 1: Machine Setup

The first step in using a water jet cutting machine is to ensure the machine is properly set up. This involves:

-

Choosing the Correct Nozzle: For cutting marble, stone, and steel, you need to select the appropriate nozzle and abrasive mix. The nozzle size will depend on the thickness and type of material you’re cutting.

-

Material Placement: Properly securing the material on the cutting bed is critical for accurate cutting. The material should be positioned precisely according to the cutting plan or blueprint.

-

Water Pressure Adjustment: Water jet machines can operate at varying pressures, typically ranging from 30,000 to 60,000 psi (pounds per square inch). For hard materials like steel, a higher pressure is generally required, while softer materials might only need a lower pressure setting.

Step 2: Calibration and Test Cutting

Before beginning the main cutting process, it’s recommended to perform a test cut on a small sample piece of the material. This will help ensure the settings (pressure, speed, nozzle type, etc.) are accurate. Calibration is essential to avoid material wastage and ensure high-quality cuts.

Step 3: Begin Cutting

Once the machine is calibrated and the material is in place, the operator can begin the cutting process. The machine will precisely follow the digital path set in the CAD/CAM software. The high-pressure water jet is directed onto the material, cutting through it with remarkable accuracy.

-

Marble and Stone: Water jet cutting is perfect for intricate stonework, such as tiles, sculptures, and architectural elements. The absence of heat means that the material’s appearance and properties remain intact.

-

Steel: Water jet cutting is ideal for cutting through steel plates of varying thicknesses. It can handle both thin sheets of steel as well as thicker, tougher steel components, making it a go-to solution for industries like automotive manufacturing, aerospace, and metal fabrication.

Step 4: Post-Cutting Inspection

After the cutting process is complete, it’s important to inspect the cut edges and overall accuracy of the cut. Water jet cutting leaves smooth, burr-free edges, but a final inspection ensures that the cut has met the desired specifications. If needed, the material can be cleaned to remove any residual abrasive particles.

Key Things to Keep in Mind When Using a Water Jet Cutter

While water jet cutting offers numerous benefits, there are a few considerations to keep in mind to ensure the best results:

-

Water Quality: The quality of the water used in the cutting process is crucial. Impurities in the water can affect the performance of the machine and cause damage to the material. Using filtered or purified water is highly recommended.

-

Abrasive Materials: When cutting stone or steel, abrasives such as garnet are often mixed with the water. Ensure the abrasive material is of high quality and suited to the hardness of the material you’re cutting.

-

Material Thickness: Different materials and thicknesses may require different water pressure settings. Always refer to manufacturer guidelines and adjust the pressure accordingly to achieve the best cut.

-

Safety Considerations: Although water jet cutting is safer than other methods, it’s still essential to follow proper safety procedures, including wearing protective gear and ensuring the work area is secure.

Applications of Water Jet Cutting for Marble, Stone, and Steel

Water jet cutting machines are widely used in various industries due to their ability to cut a range of materials precisely. Here are some common applications:

Marble and Stone

-

Architectural Stonework: Water jet cutting is commonly used in the construction industry for creating intricate stone designs such as countertops, flooring tiles, and decorative panels.

-

Artistic Stone Carving: Artists use water jet cutting for creating sculptures and custom carvings in stone or marble. The precision and lack of heat damage make it ideal for fine art projects.

Steel and Metal

-

Industrial Manufacturing: Water jet cutters are used extensively in the manufacturing industry for cutting steel plates, components, and structural parts.

-

Aerospace and Automotive: In aerospace and automotive industries, precision cuts are essential for making parts that meet strict specifications. Water jet cutting is often employed in these fields due to its ability to cut thick steel and metal without warping.

Conclusion: Why Choose FORSUN CNC Machinery?

Jinan FORSUN CNC Machinery Co., Ltd. has been providing high-quality CNC machines for over 20 years, including advanced water jet cutting systems. Our expertise in producing top-tier CNC machinery ensures that our customers receive the most efficient and reliable machines for their production needs.

Our 2025 CNC Water Jet Cutting Machines are designed to offer exceptional performance, precision, and versatility in cutting marble, stone, steel, and other tough materials. Whether you’re in the stone fabrication business or working with metals, FORSUN’s water jet cutters are engineered to handle the toughest materials while ensuring accuracy and minimal waste.

If you’re looking for a reliable and efficient water jet cutting solution, FORSUN has the expertise and the equipment you need. Contact us today to learn more about our range of CNC machines and how they can help streamline your production process.

Get in touch with us now for more details about our cutting-edge CNC Water Jet Cutting Machines!