The 150W automatic lifting CO2 laser cutting machine is designed for processing a variety of non-metallic materials, including bamboo, crystal, horn, paper, plexiglass, marble, cloth, leather, rubber, and plastic. This machine excels at cutting and surface engraving for products such as clothing, embroidery, fabric toys, household items, handbags, gloves, toys, and leather goods. It also offers precise cutting capabilities for non-metallic sheets like acrylic and medium-density decorative boards, which are widely used in crafts, models, advertisements, decorations, electrical appliances, and plastics.

What is The Best CNC Router for My Business?

Machine Configuration of 150W Automatic lifting CO2 Laser Cutting Machine

- Working area:1300mm*900mm

- With a honeycomb work table

- 100W RECI Laser Tube

- PMI Linear Guides

- With water chiller CW5000

- With 1.5 years warranty

- 1PH 220V 60HZ

- Plywood case package

- Ruida 6442S controller system: Support multiple languages, color layering, offline work, engraving, and cutting at the same time, size compensation

- Brand stepper motor: High operating accuracy, high-temperature resistance, can withstand high temperature caused by the high-speed operation, low noise.

Machine Video of 150W Automatic lifting CO2 Laser Cutting Machine

Machine Pictures

Control Panel

Knife Table

Laser Cutting Head

Laser Tube

Mirror Holder

Stepper Motor

Applicable materials

Non-metallic materials such as wood products, paper, plastic, rubber, acrylic, bamboo, marble, two-color plates, glass, wine bottles, etc.

Application industry

Advertising signs, handicrafts, prizes and trophies, paper-cutting, architectural models, lighting fixtures, printing and packaging, electronic appliances, photo frame albums, clothing leather, and other industries.

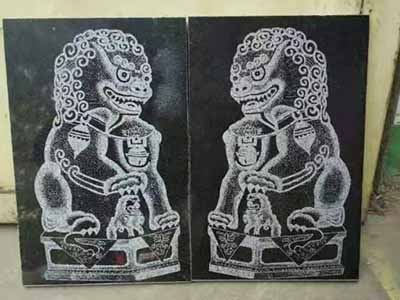

150W Automatic lifting CO2 Laser Cutting Machine Projects

Parameter Data of 150W Automatic lifting CO2 Laser Cutting Machine

| Machine model | FS 1390 150W CO2 Laser Cutting Machine |

| Laser type | Sealed CO2 laser tube, wavelenght:10:64μm |

| Laser power | 100W |

| Cooling mode | Circulating water cooling |

| Laser power control | 0-100% software control |

| Control system | Ruida 6442S controller system |

| Max. engraving speed | 60000mm/min |

| Max cutting speed | 50000mm/min |

| Repetition accuracy | ≤±0.01mm |

| Min. Letter | Chinese:1.5mm, English:1mm |

| Table size | 900*600mm |

| Working voltage | 110V/220V.50-60HZ |

| Working conditions | temperature:0-45℃,humidity:5%-95% |

| Control software language | English/Chinese |

| File formats | *.plt,*.dst,*.dxf,*.bmp,*.dwg,*.ai,*.las,*.doc |

| Mesa | Blade, honeycomb, lifting (optional) |

| Operating Voltage | 1PH 220V 60HZ |

Cutting Parameters

| Laser Power | Acrylic | Wood | MDF |

| 80 ~ 100w | 10mm | 10mm | 5mm |

| 100 ~ 130w | 15mm | 13mm | 7mm |

| 130 ~ 150w | 20mm | 18mm | 10mm |

Machine Features of 150W Automatic lifting CO2 Laser Cutting Machine:

- The imported high-precision linear guide drive ensures a stable optical laser path and movement, resulting in superior cutting and engraving effects. The advanced Ruida control system offers fast speed and simple operation, enabling rapid engraving and cutting. An optional electric lift table makes it convenient to process thicker materials, and an optional rotary attachment allows for engraving cylindrical objects like wine bottles and pen vases.

- To enhance work efficiency, we can equip the machine with double or multiple laser heads. The high-speed laser cutting machine can be fitted with laser tubes of varying power, including 60W, 80W, 100W, 130W, 150W, and 180W. This versatile machine can precisely engrave and cut a variety of non-metal materials such as acrylic, double-color plates, PVC, wood, MDF, leather, paper, and cloth. The durable, high-speed laser head provides more precision and is made of metal, reducing consumable costs.

- The open blade working table, made of specially treated material, is resistant to wear and easy to operate, making it suitable for all kinds of hard materials. With lower investment, operating, and maintenance costs, this machine offers cost-effective solutions. Laser cutting is particularly advantageous for processing difficult-to-cut materials, such as those with high strength and toughness or complex shapes, making CNC laser cutting highly valuable in China’s manufacturing industry.

FAQ

Q: How can I make sure that this laser machine is suitable for my work?

A: You can describe what you will use this machine for, such as your working material (metal or non-metal), maximum working area, and cutting thickness, we will provide you with a machine suitable for your work

Q: Are you a factory or a trading company?

A: We are a factory with import and export rights. Many customers come here to visit our factory every year. You are welcome to visit our factory at any time.

Q: This is my first time using this machine. Is it easy to operate?

A: We have manuals and operating videos, which can teach you how to use it. If there are still many questions, we can teach you online. If necessary, our engineers can go abroad to help you.

Q: What should I do if there are any problems after receiving the machine?

A: Free after-sales service will be provided during the service life of the machine, and we will provide you with 24-hour online service

Q: What is your minimum order quantity?

A: Our MOQ is one machine. We can send the machine directly to your national port or your factory, please tell us your port name or detailed address. The best shipping and machine prices will be sent to you.

Reviews

There are no reviews yet.